How xis.ai Detects Defects in Metal Parts

Recent Post:

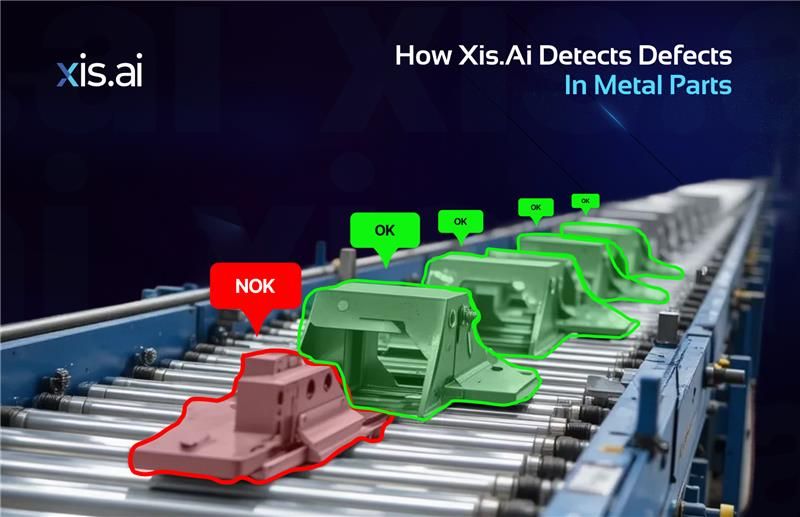

At xis.ai our mission is to redefine industrial quality inspection using cutting‑edge AI vision technology. Detecting defects in metal parts — from surface scratches to internal anomalies — is a persistent challenge in manufacturing. Traditional manual checks and rule‑based systems struggle with scale, consistency, and subtle defect patterns. Our AI‑powered platform addresses these challenges by combining advanced imaging, machine learning, and real‑time edge execution to deliver highly accurate, automated inspection across production lines.

The xis.ai Approach to AI‑Driven Defect Detection

We begin with high‑quality visual data acquisition. Whether the application uses industrial cameras, X‑rays, or CT systems, xis.ai consumes this image data and transforms it into actionable inspection insights. Our platform’s pipeline is designed to be no‑code and accessible, enabling manufacturers to import data, annotate defects, train AI models, test them, and deploy into real‑time production workflows — all without deep AI expertise.

Inside our system, computer vision and machine learning algorithms work together to extract meaningful patterns from visual data. Instead of relying on fixed rules, xis.ai models learn from examples — recognizing defect features such as cracks, dents, porosity, and geometric distortions that could compromise part integrity.

Core AI Techniques Powering xis.ai

Convolutional Neural Networks (CNNs)

CNN‑based models form the backbone of our image analysis. These deep learning architectures scan pixel‑level information to discern textures, shapes, and visual irregularities that signify defects — even those imperceptible to human inspectors. They excel in understanding spatial hierarchies, making them especially effective for diverse metal part geometries.

Anomaly Detection & Unsupervised Learning

Not all defect types can be pre‑labeled. xis.ai incorporates anomaly detection models that learn the normal appearance of a metal part and flag deviations automatically. This is especially useful for catching unknown or rare defects that haven’t been previously categorized.

3D Imaging & Volumetric Analysis

Many high‑precision metal parts require more than surface inspection. By incorporating 3D CT data where available, xis.ai evaluates internal structures and hidden defects, such as voids, inclusions, or density non‑uniformities that surface imaging alone cannot reveal.

Real‑Time Edge Inference

Our platform supports edge AI deployment, meaning models run locally at the machine level with minimal latency. For high‑speed production environments, this rapid inference is crucial — providing instant pass/fail decisions and actionable alerts without cloud dependency.

How XIS.ai Enhances Manufacturing Quality

- Accuracy & Sensitivity: Detect defects at micro‑scale that human inspection often misses.

- Consistency & Repeatability: Standardize inspection performance across shifts, products, and lines.

- Speed & Throughput: Real‑time inference keeps pace with high‑volume manufacturing.

- Accessibility: No deep AI expertise required thanks to our intuitive platform.

- Scalability: Models and dashboards scale across facilities for unified quality oversight.

xis.ai in Action: From Training to Deployment

Our process is deliberately straightforward:

- Import Data: Bring in images or scans from your cameras and sensors.

- Annotate Defects: Use our annotation tools to label example defects.

- Train Models: Train vision‑AI models tailored to your inspection needs.

- Test Performance: Validate accuracy and optimize thresholds.

- Deploy in Real Time: Push models to production with edge execution, where they analyze parts instantly.

This end‑to‑end workflow ensures that manufacturers can quickly go from concept to deployed inspection without months of integration or custom coding.

Frequently Asked Questions (FAQ)

What kinds of metal defects can xis.ai detect?

xis.ai can detect surface anomalies like cracks, scratches, dents, and texture irregularities, as well as internal issues like voids or inclusions when paired with 3D imaging data.

Do I need AI expertise to use xis.ai?

No. xis.ai is a no‑code AI platform that guides you through data import, annotation, model training, and deployment with an intuitive UI.

Can xis.ai integrate with my existing inspection cameras?

Yes — the platform supports integration with standard industrial cameras and imaging hardware, enabling you to leverage existing infrastructure.

Does xis.ai run on the factory floor or in the cloud?

XIS.ai supports edge AI deployment, which means models run locally on site for real‑time inspection. This minimizes latency and enhances reliability.

Can xis.ai help improve overall production efficiency?

Absolutely. By automating defect detection and reducing false rejects, xis.ai lowers rework costs, reduces scrap, and helps manufacturers maintain consistent quality at scale.

Comment

0Comments

No comments yet.