Role of Computer Vision in Detecting Surface Imperfections

Recent Post:

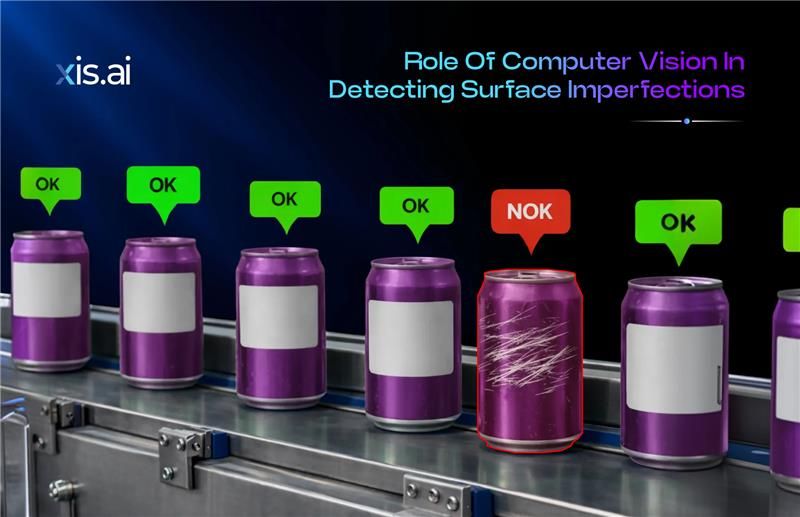

The role of computer vision in detecting surface imperfections has become increasingly critical in modern manufacturing. As production speeds increase and quality standards tighten, traditional manual inspection methods struggle to keep up. Human inspection is often subjective, inconsistent, and time-consuming.

Computer vision systems, powered by AI and machine learning, offer automated, accurate, and scalable solutions for identifying even microscopic defects on surfaces — in real time.

From automotive panels to semiconductor wafers, computer vision is transforming how industries approach quality control.

What Are Surface Imperfections?

Surface imperfections are irregularities or defects that affect the quality, functionality, or appearance of a product. These may include:

- Scratches

- Cracks

- Dents

- Corrosion

- Discoloration

- Porosity

- Contamination

- Coating inconsistencies

In industries like aerospace, electronics, automotive, and medical devices, even minor surface defects can lead to product failure, safety risks, or regulatory non-compliance.

How Computer Vision Detects Surface Imperfections

1. High-Resolution Image Capture

Industrial cameras capture high-definition images under controlled lighting conditions. Specialized lighting techniques — such as structured light or dark-field illumination — enhance surface irregularities that are invisible to the naked eye.

2. Image Preprocessing

Before analysis, images undergo preprocessing steps like:

- Noise reduction

- Contrast enhancement

- Edge detection

- Background normalization

This ensures that defects stand out clearly for algorithmic analysis.

3. AI-Powered Defect Detection

Machine learning and deep learning models analyze the processed images to:

- Identify anomalies

- Classify defect types

- Measure defect size and severity

- Compare against acceptable tolerance thresholds

Convolutional Neural Networks (CNNs) are particularly effective in recognizing complex texture variations and subtle surface inconsistencies.

4. Real-Time Decision Making

Advanced systems can detect and flag defects within milliseconds. Integrated with production lines, these systems can:

- Reject faulty products automatically

- Trigger alerts

- Adjust machine parameters

- Generate inspection reports

This creates a closed-loop quality control system.

Why Traditional Inspection Falls Short

Manual inspection depends heavily on operator experience and concentration. Over time, fatigue reduces accuracy. Additionally:

- Small defects are easily overlooked

- Inspection speed is limited

- Subjectivity leads to inconsistent results

- Labor costs increase operational expenses

Computer vision eliminates these limitations by offering consistent, repeatable, and objective evaluation.

Key Benefits of Computer Vision in Surface Inspection

1. Improved Accuracy

AI systems detect micro-defects that humans might miss, reducing false negatives.

2. Consistency

Inspection criteria remain constant across shifts and production batches.

3. Higher Throughput

Automated inspection supports high-speed production lines without slowing operations.

4. Cost Efficiency

Reduced rework, lower scrap rates, and minimized warranty claims lead to long-term savings.

5. Data-Driven Insights

Inspection systems collect and analyze defect data, helping manufacturers identify recurring issues and optimize processes.

Applications Across Industries

Automotive: Detection of paint defects, weld cracks, and body panel irregularities.

Electronics & Semiconductor: Inspection of PCB surfaces, solder joints, and wafer defects.

Aerospace: Identification of micro-cracks and coating imperfections on structural components.

Metal & Steel Manufacturing: Surface crack detection, corrosion monitoring, and texture analysis.

Consumer Goods: Quality assurance for packaging, glass surfaces, and finished products.

Deep Learning vs. Rule-Based Vision Systems

Feature | Rule-based Systems | AI / Deep Learning Systems-----------------------------------------------------------------------Setup | Manual parameter tuning | Learns from dataFlexibility | Limited to predefined defects | Detects new or unknown patternsAccuracy | Moderate | HighScalability | Challenging | Highly scalableModern manufacturers are increasingly shifting toward AI-based systems due to their adaptability and long-term performance.

Challenges in Surface Defect Detection

While powerful, computer vision systems must overcome challenges such as:

- Variations in lighting conditions

- Reflective or textured surfaces

- High-speed production constraints

- Requirement for large, labeled datasets

Advanced AI models, combined with optimized hardware and domain expertise, help address these complexities.

The Future of Computer Vision in Quality Inspection

The next phase of innovation includes:

- Edge AI for real-time on-device processing

- 3D vision systems for depth-based defect detection

- Self-learning systems that improve over time

- Integration with Industry 4.0 smart factories

As AI models become more robust and computational power increases, defect detection systems will continue to become more autonomous and intelligent.

Conclusion

The role of computer vision in detecting surface imperfections is redefining industrial quality control. By combining high-resolution imaging with AI-driven analysis, manufacturers can achieve higher accuracy, improved efficiency, and data-backed process optimization.

In an era where precision and speed define competitiveness, computer vision is no longer optional — it is essential.

Frequently Asked Questions

What is computer vision in surface inspection?

Computer vision in surface inspection uses cameras and AI algorithms to automatically detect defects such as cracks, scratches, or discoloration on product surfaces.

How accurate is AI-based defect detection?

AI-based systems can achieve very high accuracy, often exceeding human inspection, especially for micro-defects and repetitive inspection tasks.

Can computer vision detect microscopic defects?

Yes. With high-resolution cameras and proper lighting, computer vision systems can identify defects at microscopic levels.

What industries benefit most from computer vision inspection?

Automotive, aerospace, electronics, semiconductor, metal manufacturing, and medical device industries benefit significantly.

Is computer vision expensive to implement?

While initial setup costs can be significant, long-term savings from reduced scrap, rework, and labor often make it cost-effective.

What is the difference between rule-based and AI-based inspection?

Rule-based systems follow predefined parameters, while AI-based systems learn from data and can detect new or complex defect patterns.

Comment

0Comments

No comments yet.