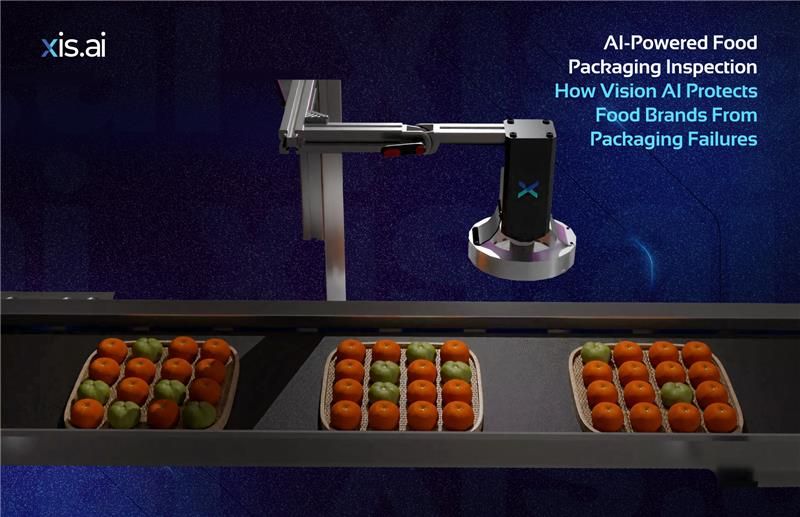

AI-Powered Food Packaging Inspection: How Vision AI Protects Food Brands from Packaging Failures

Recent Post:

Why Packaging Defects Are a Serious Risk for Food Safety

Food packaging is the last barrier between a product and contamination. Even a minor defect — a loose cap, an incomplete seal, or incorrect fill level — can compromise food safety, shorten shelf life, and damage brand reputation.

Traditional manual inspections and rule-based vision systems struggle to keep up with high-speed production lines. Human fatigue, inconsistent lighting, and limited sampling often allow defects to pass unnoticed. As production volumes increase and regulatory scrutiny tightens, food manufacturers need inspection systems that are faster, smarter, and more reliable.

This is where AI-powered food packaging inspection using Vision AI platforms like xis.ai is transforming quality control from reactive to predictive.

1. Common Packaging Defects That Impact Food Quality

Even modern packaging lines experience recurring issues that affect compliance, safety, and customer satisfaction.

2. Missing Caps or Lids

Unsealed containers expose food products to air, bacteria, and moisture. A single missing cap can trigger costly recalls and regulatory violations.

3. Seal Gaps and Improper Sealing

Weak or incomplete seals allow leaks and microbial contamination, especially in dairy, sauces, beverages, and ready-to-eat products.

4. Underfilled or Overfilled Packs

Incorrect fill levels lead to regulatory non-compliance, customer dissatisfaction, increased material waste, and inconsistent shelf-life performance.

Detecting these issues consistently at production speed is extremely difficult without intelligent automation.

How xis.ai Works – Intelligent Visual Inspection at Production Speed

xis.ai applies advanced Vision AI models to monitor packaging lines continuously and accurately.

1. AI-Based Visual Detection

High-resolution cameras capture images of every product moving through the line. AI models analyze each frame to identify defects such as missing or misaligned caps, seal integrity issues, incorrect fill levels, deformed packaging, and label placement errors.

Unlike rigid rule-based systems, the AI adapts to real-world variations in lighting, product shape, and packaging material.

2. Real-Time Alerts and Actionable Insights

When a defect is detected, xis.ai immediately triggers alerts for operators and quality teams. This enables instant rejection of faulty units, rapid root-cause identification, and continuous improvement through defect trend analysis.

The result is faster response time and fewer defective products reaching the market.

Results for Food Manufacturers Using Vision AI

Implementing AI-powered inspection delivers measurable operational and commercial benefits.

1. Reduced Recalls and Compliance Risk

Early defect detection prevents contaminated or non-compliant products from leaving the factory, minimizing regulatory exposure and recall costs.

2. Improved Shelf-Life Consistency

Accurate sealing and fill control help maintain product freshness and consistency across batches.

3. Increased Customer Trust and Brand Protection

Consumers expect safe, reliable packaging. Automated inspection strengthens brand credibility and reduces negative customer experiences.

4. Operational Efficiency

Automated inspection reduces dependency on manual checks, improves throughput, and stabilizes production quality at scale.

Case Study Example – Beverage Bottling Line Optimization

A mid-sized beverage manufacturer faced frequent complaints related to loose caps and inconsistent fill levels. Manual inspection could only sample a small percentage of total output, allowing defects to slip through.

After deploying xis.ai, the system monitored 100% of bottles in real time, missing caps were detected instantly and rejected automatically, fill-level accuracy improved by over 30%, monthly customer complaints dropped significantly, and quality audit preparation time was reduced due to automated reporting.

The manufacturer achieved faster ROI through reduced waste, fewer returns, and improved operational visibility.

Conclusion – The Future of Food Quality Control Is Automated

Food safety standards are rising, production speeds are increasing, and customer expectations continue to grow. Manual inspection alone can no longer guarantee consistent packaging quality.

AI-powered food packaging inspection with platforms like xis.ai delivers scalable, real-time, and highly accurate defect detection that protects both consumers and brand reputation.

Ready to modernize your quality inspection process? Discover how xis.ai can help your facility eliminate packaging defects, reduce recalls, and strengthen production confidence. Contact our team to schedule a demo today.

Frequently Asked Questions

1. What is AI-powered food packaging inspection?

It is an automated quality control system that uses computer vision and artificial intelligence to detect packaging defects in real time during production.

2. Can Vision AI work on high-speed production lines?

Yes. Modern Vision AI platforms like xis.ai are designed to process thousands of images per minute without slowing production.

3. What types of defects can xis.ai detect?

xis.ai can identify missing caps, seal gaps, incorrect fill levels, damaged packaging, labeling issues, and other visual anomalies.

4. Does AI inspection replace human inspectors completely?

AI reduces dependency on manual inspection but complements quality teams by providing consistent monitoring, analytics, and faster response.

5. How quickly can manufacturers see ROI after implementation?

Most manufacturers see ROI within months due to reduced waste, fewer recalls, lower rework costs, and improved production efficiency.

Comment

0Comments

No comments yet.