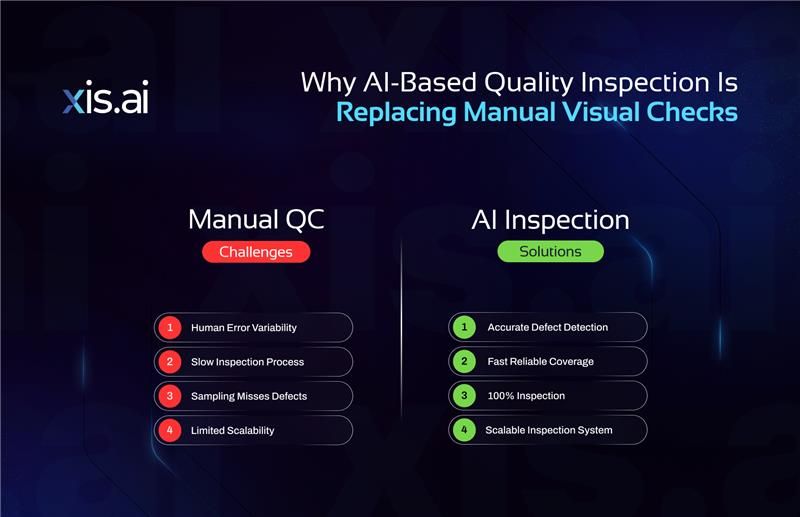

Why AI-Based Quality Inspection Is Replacing Manual Visual Checks

Recent Post:

Manual Visual Inspection Has Reached Its Practical Limits

Manual visual inspection depends on human attention, consistency, and experience. In controlled environments and low volumes, this approach can be effective. However, modern production lines operate at high speed, tight tolerances, and increase product complexity. Human inspectors cannot reliably sustain the same level of accuracy across long shifts or large inspection volumes.

Small defects, gradual dimensional drift, and internal anomalies often escape visual detection. Inspection outcomes vary between operators, lighting conditions, and fatigue levels. This variability introduces hidden quality risk and limits scalability.

AI Inspection Applies Consistent Decision Logic

AI-based quality inspection uses trained models to evaluate every unit against the same learned criteria. The system does not fatigue, does not drift in judgment, and applies consistent thresholds across all shifts and locations. High-resolution sensors capture detailed features, and the model evaluates patterns rather than isolated pixels or simple rules.

This consistency eliminates subjective interpretation and stabilizes inspection performance.

Key advantages include:

- Repeatable decision making

- Stable accuracy over time

- Uniform standards across production sites

AI Detects What Human Vision Cannot

Human vision is limited by resolution, depth perception, and contrast sensitivity. AI inspection systems analyze data from sensors that reveal surface texture, geometry, internal structure, and material variation. Subtle defects that appear visually acceptable can still be detected through pattern deviation analysis.

This capability improves early defect containment and reduces quality escapes.

Real-Time Processing Matches Production Speed

AI inference operates in milliseconds at the production edge. Inspection decisions occur without slowing the line. Defective parts are isolated immediately, preventing downstream processing of nonconforming components.

Real-time response enables:

- Immediate rejection and containment

- Faster corrective action

- Reduced accumulation of hidden defects

Automated Data Enables Traceability

Every inspection generates structured data including images, classification results, timestamps, and confidence levels. This creates a continuous digital quality record without manual documentation.

Benefits include:

- Faster root cause analysis

- Audit-ready traceability

- Process trend visibility

Manual Inspection Does Not Scale Efficiently

Scaling manual inspection requires proportional increases in labor, training, supervision, and quality variability management. AI inspection scales through software replication and standardized deployment, allowing consistent quality control across multiple lines and facilities.

Conclusion

Manual visual inspection cannot maintain the accuracy, speed, and consistency required by modern manufacturing. AI-based quality inspection replaces subjective judgment with data-driven, repeatable decision making. It improves defect detection, supports real-time response, enables traceability, and scales efficiently across production environments.

As manufacturing complexity increases, AI inspection becomes a practical necessity rather than a technology upgrade.

Frequently Asked Questions

1. Why is AI inspection more consistent than manual inspection?

AI applies the same trained decision logic to every unit without fatigue or subjective variation.

2. Can AI detect defects invisible to human inspectors?

Yes. AI analyzes high-resolution and multi-modal sensor data beyond human visual limits.

3. Does AI inspection slow down production lines?

No. Real-time edge processing enables inspection without impacting throughput.

4. How does AI improve quality traceability?

All inspection results are automatically recorded as structured digital data.

5. Is AI inspection difficult to scale across factories?

No. Once validated, models and systems can be replicated consistently across sites.

Comment

0Comments

No comments yet.