How Robots and AI Strengthen Quality Inspection Protocols

Recent Post:

Quality assurance in manufacturing ensures precision, detects defects, and maintains standards for high-quality products.

This division helps differentiate the reliability and consistency of products, ensuring they meet industry standards and customer expectations.

With the help of Vision-Guided Robotics (VGR), the quality inspection process has been automated for intricate parts. VGR is the integration of AI into a robotic in which automatic cameras and sensors are mounted, allowing for proper analysis and defect identification of objects.

VGR is more efficient than manual inspection methods as it does not work along fixed routes. In contrast, VGR adjusts its focus and inspections on the go. This makes processes significantly easier and saves a lot of time. This use of technology is especially beneficial for industries that deal with massive delicate structures, or highly sensitive products.

This blog article aims to analyze the collaboration of AI and robots to enhance reliance, speed, and accuracy during quality inspections in different industries.

How AI Enhances Robots in Quality Control

Robots have been part of the manufacturing and warehouse activities for a long period now, with their use dating back to the 1960s when they began performing simple and repetitive tasks. However, the advent of Artificial Intelligence (AI), and in particular Machine Learning (ML) and computer vision, has enhanced the scope of what robots can do. While machines excel at carrying out physical work, AI-powered machines are capable of making informed judgments based on data in real-time.

Automated systems can analyze visual data and recognize patterns or anomalies that are not perceivable to the human eye, such as minute cracks, misalignments, and subtle shifts in color in the manufactured parts. Over time, algorithms for machine learning become better with time as they process more and more data thereby increasing the accuracy of defect detection and consequently improving quality control. In some industries, AI-powered robots with advanced cameras and sensors now automatically inspect products with more accuracy than ever, spotting defects in the surface and checking the structure. These Collaborative Robots (Cobots) increase the efficiency of operation improving workflow and decision making. With the further development and integration of AI in robotics, quality inspection is faster, more precise, and more flexible.

The Synergy Between AI and Collaborative Robots (Cobots)

Collaborative robots, or Cobots, enhance the field of quality inspection by assisting humans in maintaining the human touch of the workforce. Unlike regular robots that work in isolation, Cobots support personnel by automating tedious and strenuous work.

In quality inspection, AI-powered Cobots can aid humans in putting parts into boxes, measuring parts, or carrying heavy components. It enables human employees to concentrate on tier-two decisions, where they can apply their judgment. AI gradually teaches Cobots while making the inspection flows more seamless and streamlined.

These collaborations tend to increase productivity while at the same time making the workplace safer where humans do critical thinking and AI undertakes basic inspection roles.

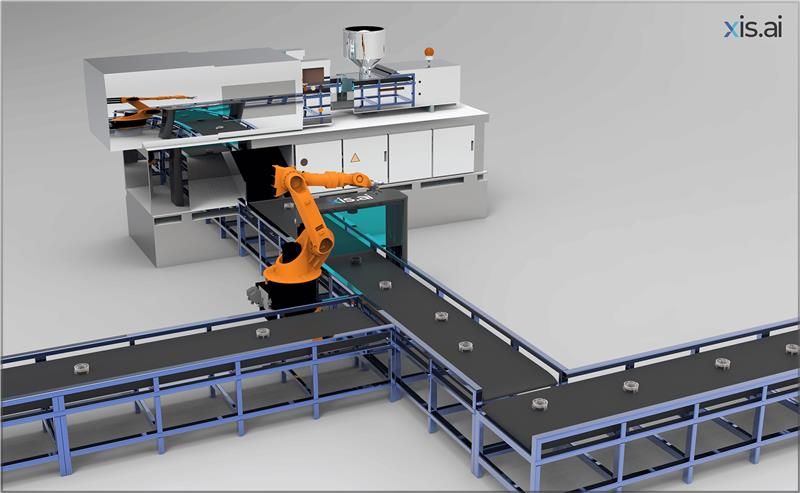

Industrial Robots:

Industrial robots handle repetitive inspection tasks with speed and precision. They ensure consistent accuracy, minimizing human error and improving efficiency.

How Robots and AI Work Together to Improve Quality Inspection Protocols?

The collaboration between robots and AI brings additional opportunities to perfect quality inspection operations, enabling them to be more precise, flexible, and efficient than before.

- Computer Vision and AI-powered Inspection

As robots equipped with high-resolution cameras and advanced sensors are capable of interpreting visual information through AI-powered computer vision, they can ‘see. AI-powered visual interpretation is done using deep learning models that allow for defect detection, measurement of tolerances, and verification of product specifications. The ability to recognize complex visual patterns enables AI-powered robots to detect complex product anomalies, making them invaluable tools for manufacturers.

- Machine Learning For Continuous Improvement

Inspecting robots are programmed with algorithms that enable learning from valid previous inspections. With every defective product the AI system identifies, it gets closer to the required performance level or the adaptive target of the presented production scheme. This learning procedure continuously enables robots to not only respond to the existing problems but also predict the probable issues, providing flexibility and customization of the quality assurance methods.

- Automated Robotics with IoT Capabilities for Real-Time Analytics

AI enables the integration of robotics with the IoT by capturing real-time data from diverse sensors positioned along the production lines. This information is studied through AI algorithms to identify quality patterns, foresee equipment malfunctions, and dynamically modify production plans. Being able to respond to these issues in real time ensures that the quality remains on a high level.

- Advanced Robotic Sensors for Precision

Robots are equipped with the latest sensors, including 3D cameras, infrared cameras, and laser scanners, among others, designed to malfunction and capture the product's metric units, figures, and surface details. These sensors identify defects that would otherwise bypass conventional inspection methods and the eye.

Applications of AI and Robotics in Quality Inspection

At this moment, businesses are already harvesting the benefits of quite intelligent robotics and artificial intelligence-powered quality checks.

- Automotive Industry: Robots with AI vision systems analyze body panels for defects and evaluate the fit of the various parts into the vehicle. These robots ensure that the components are up to safety regulations and standards.

- Automotive Manufacturing: When it comes to manufacturing vehicles, accuracy is needed, for welding is an integral part of it. AI-integrated robots are deployed to aid in the inspection of welds, searching for cracks, inconsistencies, and other structural defects. These robots check on the seams of the welds in real time to guarantee their quality and reliability.

- Electronics Manufacturing: Robotics and AI are utilized to check for micro defects on circuit boards including component alignment, soldering imperfections, or various other problems that could jeopardize the strength of the product.

- Component Testing: Robots verify the functionality and placement of electronic components on devices like smartphones and laptops.

- Pharmaceutical Industry: AI robots help to scan for packaging flaws, which include wrong labels, cross-contamination, and broken seals. This ensures that the final product is safe and within standards.

Challenges & Considerations:

The application of AI and robotics to the field of quality inspection has its advantages, but certain significant challenges also exist, such as:

- Substantial Capital Investment: The AI-based robotic inspection system requires a high initial capital expenditure to implement the concept. This involves investment in equipment and the building of application-specific software.

- Data Management: First, AI needs access to a large volume of high-quality information to function well. Inconsistent and unorganized data will always breed inaccurate results. Hence, there is a need for manufacturers to guarantee the data utilized in training AI algorithms is complete and accurate.

- System Compatibility: The application of robotics in AI-enabled systems may demand significant changes to existing production processes. Old structures will have to be modernized or discarded so that they can function with modern robotic systems.

- Labor Deficiencies: As more systems are automated and integrated with AI, there will arise a need for proficiency in the operational and maintenance aspects of these systems. Empowering these workers to take command of these technologies will be fundamental.

The Path Forward:

The perspective in the quality checking domain indicates that with the arrival of completely automated systems, which function without the presence of a human, there shall be unmanned AI and robot-operated systems that shall enhance productivity and precision per inspection. Further, AI and robotic systems will go a step further and tend to problems that may occur during production even before the problem arises, a predictive maintenance approach. This technology will continue to revolutionize and improve the manufacturing industries with enhanced accuracy, scalability, and reduced costs. It has become apparent that there is no option for granting quality inspection AI and robotic assistance if the business is to remain relevant in the market because this is no longer a question of choice, but rather a necessity for efficiency and improved processes.

Comment

0Comments

No comments yet.