How Industrial Barcodes Improve Supply Chain Efficiency and Traceability

Recent Post:

Barcodes visually represent numbers, characters, and data in a format readable by machines. They appear as parallel lines (1D) or patterns (2D).

It can be displayed in two styles, a sequence of parallel lines (1D) or as patterns (2D).

Barcodes consist of spaces and bars that have different widths which can be read by an optical barcode scanner or a smartphone. These scanners can also be used for reading objects with tracking information or serial numbers. Most modern products found in supermarkets, convenience stores, and other shops are embedded with this unique design.

What are Industrial Barcodes?

Industrial barcodes are used in factories, warehouses, and supply chains, where there is a high demand for goods. They need to be accurate, and efficient and enhance performance at all levels, and Industrial barcodes achieve that effortlessly. Different types of barcodes serve various purposes, and these are no different.

Types of Barcodes

As for industrial barcodes, need to determine type, and they are divided into subcategories for better classification like inventory management, asset tracking, logistics, and manufacturing. They are split into two types, 1D or Linear Barcodes, and 2D or Matrix Barcodes.

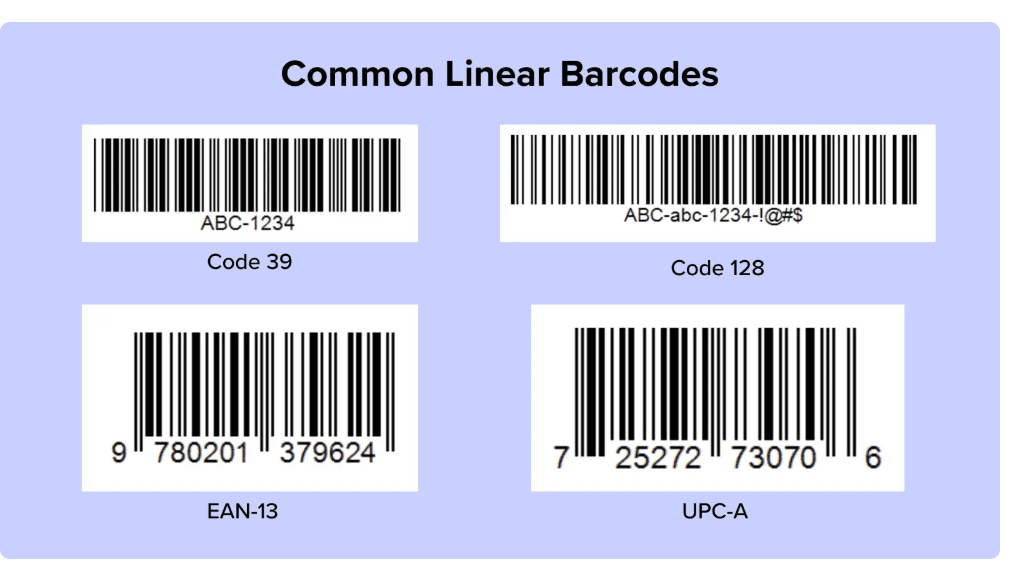

1D Barcodes (Linear Barcodes)

1D barcodes are the oldest and most common method of using barcodes. Data is presented in a sequence of black and white vertical bars, with alphanumeric information encoded into it. It can be accessed using a database for requirement, and 1D barcodes prove to be the most common in retail, logistics, and asset management.

Commonly Used 1D Barcode Symbologies:

UPC: Universal Product Code is used around the world by retail stores.

EAN: This barcode is primarily used in Europe for identifying a product.

Code 39: Encoding 39 alphanumeric characters, Code 39 is often utilized in the defense and manufacturing sector.

Code 128: A Lo-Hi Code allowing scanning to support all ASCII 128 characters. It finds popularity in logistics and shipping.

Key Features of 1D Barcodes:

- The Barcode order of reading presented by the scanner starts from left to right.

- Make sure to leave space (white area) on both sides for accurate and reliable scanning.

- Usually, incorporate a check digit to ensure the readability and accuracy of the data provided.

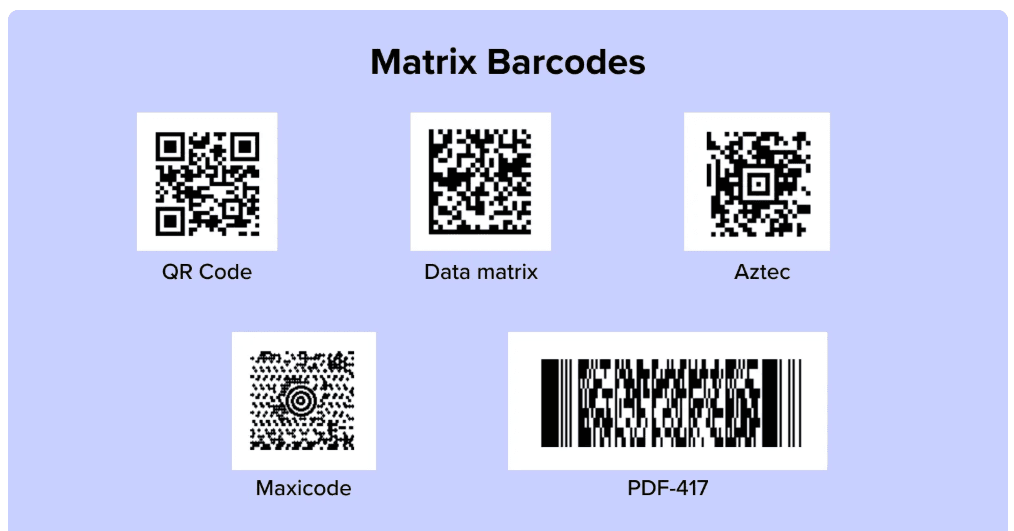

2D Barcodes (Matrix Barcodes)

In contrast to 1D barcodes, 2D barcodes save information horizontally, as well as vertically, thus having the ability to present far more data. Their wide application in medicine and electronics is due to their high data storage capacity and automatic error correction.

Common 2D Barcode Symbologies:

QR Code: This code is often used for advertising, payments, and inventory systems.

Data Matrix: Frequently us in the manufacturing and medical industries for small item coding.

PDF417: Used in traffic identification documents and logistics of transport.

Aztec Code: Commonly used for tickets and on public transport.

Maxi-Code: 2D matrix barcode developed by UPS for high-speed package tracking. It features a bullseye pattern, supports error correction, and is optimized for logistics and automation.

Key Features of 2D Barcodes:

- Store up to 3,116 numeric or 2,335 alphanumeric characters in a single code.

- Built-in error correction, ensuring data accuracy even if the code is damaged.

- Use a finder and clocking patterns for proper orientation during scanning.

- Require vision-enabled barcode readers instead of traditional laser scanners.

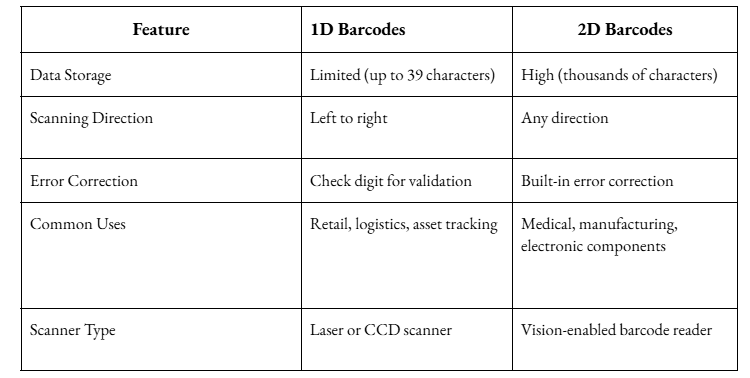

Differences: 1D vs. 2D Barcodes

How do Barcodes Work?

Barcodes are useful tools in retail, logistics, and inventory management since they can store large amounts of information within single-dimensional or two-dimensional barcodes. It is easy to view the stored information since scanners can swiftly interpret the coded information and the black-and-white pattern barcode.

1. Creating a Barcode

A barcode is created in inventory or sales software by assigning details like:

- Title of the Product

- Product Price

- Product Source

- Unique Product Name (SKU, Serial Number, etc.)

- The barcodes can now be:

- Imprinted on the surface of the label

- Stuck on the product

- Carved on a useful object

Once the barcode is created, the product’s information can be added, updated, or reviewed through the barcode system.

2. Scanning a Barcode

For barcodes to be interpreted, barcode readers are essential. They have many types, some of them are:

- Laser Scanners: Utilizes laser light to read one-dimensional barcodes.

- CCD Scanners: Employ LED sensors to accurately capture data.

- Imaging Scanners: Takes images of barcodes then decodes them for reading purposes.

- Mobile Scanners: Uses modern smartphone cameras and apps for barcode scanning.

The scanner picks the barcode information and transmits it to the computer or system for further steps.

3. Using Barcode Data

Barcodes help businesses track inventory, monitor production, and automate processes by sending data to ERP, POS, and inventory systems.

They connect with industrial networks like:

- Ethernet/IP

- PROFINET 10

- Modbus TCP/IP

With this, businesses can:

- Track inventory and raw materials

- Monitor production and shipments

- Automate logistics and quality control

The Technology Behind Barcodes

To ensure accuracy and efficiency, industrial barcode scanning relies on advanced technologies:

- Laser Scanners: Fast and reliable, commonly used in warehouses and production lines.

- Image-Based Scanners: Use optical recognition to decode barcodes, ideal for damaged or low-contrast labels.

- AI-Powered Barcode Systems: Incorporate machine learning algorithms to improve scan accuracy and reduce errors.

- IoT-Enabled Barcode Readers: Connect to cloud-based platforms for real-time data tracking and analytics.

Benefits of Barcodes

- Accuracy: Eliminates manual errors and ensures precise tracking.

- Speed: Quick scanning for fast checkout and inventory updates.

- Cost-Effective: Reduces labor and tracking costs.

- Better Inventory Management: Prevents overstocking and shortages.

- Higher Productivity: Automates data collection and reduces workload.

- Improved Tracking: Enables real-time product monitoring and recalls.

- Easy Integration: Works with ERP, POS, and inventory systems.

- Versatile: Used in retail, healthcare, logistics, and more.

Barcode Applications Across Industries

Different industries across the globe are trying to incorporate barcode systems for better efficiency, precision, and automation.

Here’s what different industries do:

1. Manufacturing:

- Monitors raw materials, work-in-progress (WIP), and finished products.

- Links barcodes with the inspection records for ensuring quality control.

- Operates automated production lines using barcode-scanning robotics.

2. Logistics and Warehousing:

- Updates inventory by scanning incoming shipments.

- Aid automated sorting systems in distribution centers.

- Uses barcode labels to monitor packages from the starting point to their delivery.

3. Retail:

- Enhances efficiency in checkout by scanning barcodes at POS devices.

- Keeps track of inventory and reorders items automatically when the stock goes below a certain level.

- Allows for price verification and promotion through linking barcodes with POS databases.

4. Healthcare and Pharmaceuticals:

- Follows and tracks medication from manufacturing until it is administered to the patient.

- Helps to ensure the safety of a patient by matching treatments with scanned wristbands.

- Controls and looks after medical devices, equipment, and hospital inventory.

5. Automotive:

- Employs barcodes in the tracking of components and parts in manufacturing JIT.

- Guarantees traceability of parts for recalls and quality assurance (QA).

- Facilitates assembly of vehicles and coordination of logistics.

6. Food and Beverage:

- Tracks ingredients and finished products throughout the supply chain.

- Ensures that Food Safety Modernization Act regulations are met.

- Automates the tracking of the date of expiry and mitigation of waste.

7. Electronics and Semiconductor:

- Follows the movements of high-value components, throughout production and distribution.

- Prohibits counterfeiting using specially serialized barcodes.

- Oversees the service and warranty records of electronic devices.

8. Aerospace & Defense:

- Employs barcodes for tracking aircraft parts and their servicing history.

- Makes sure the defense as well as aviation standards are followed.

- Optimizes logistics and supply chain for critical components.

9. E-commerce & Fulfillment Centers:

- Self-serve order picking, packing, and returns.

- Assigns different destinations for shipped goods using barcodes.

- Improves warehouse inventory control with current information.

10. Government & Public Sector:

- Employs asset tracking barcodes from office furniture to vehicles.

- Tracks documents and cuts down on paperwork mistakes.

- Assists public service identification and security systems.

Different Ways to Mark and Scan Barcodes

Barcode Marking Technologies

- Industries employ advanced barcode marking methods for durability and precision:

- Thermal & Direct Thermal Printing: Barcode Packaging labels used for retail and packing purposes.

- High-Speed Inkjet Printing: Direct marking on plastic, glass, and cardboard.

- Laser Etching: Permanent barcode engraving on metal and plastic (automotive, aerospace).

- Dot Peen Marking: Impact marking for tough metal surfaces using a pin.

- Chemical Etching: Precision barcode engraving for medical and electronic components.

- Direct Part Marking (DPM): High-durability barcodes for lifetime traceability.

Barcode Reader Technologies

Barcode scanning solutions vary by precision, speed, and data integration capabilities:

- Laser Scanners: High-speed 1D barcode reading using laser beams.

- CCD Scanners: Short-distance scanning with LED sensors is made more precise.

- Imaging Scanners: AI-driven cameras for decoding complex 1D & 2D codes.

- Handheld Scanners: Bluetooth-enabled ergonomic devices capture information on the go.

- Fixed-Mount Scanners: Automated inline scanning for production and logistics.

- Mobile Readers: AI-powered smartphone scanning apps for real-time tracking.

- RFID Scanners: Long-range, contactless barcode and tag reading for IoT integration

Best Practices for Implementing Industrial Barcode Systems

- Choose the Right Barcode Type: Ensure compatibility with your scanning devices and operational needs.

- Use Durable Labels: Industrial environments require labels that withstand heat, chemicals, and abrasion.

- Optimize Scanner Placement: Position scanners for easy access and quick reads in high-traffic areas.

- Integrate with Automation Systems: Connect barcode data with ERP, WMS, and AI-driven analytics tools.

- Regular Maintenance and Testing: Prevent scanning failures by maintaining barcode printers and readers.

xis.ai AI-powered counting and check-and-balance system. Ensure precise, real-time product monitoring and inventory verification on your production lines.

The Path Forward:

The next generation of industrial barcode systems is rapidly evolving due to AI vision systems, IoT connectivity, and blockchain tracking. The advancement of automation will further allow barcodes to be integrated with smart factories facilitating real-time data exchange, predictive maintenance, and improved visibility of the supply chain.

Through cloud-based services and RFID, tracking will be extended beyond usual scanning. AI image recognition technology will allow barcodes to be read with greater ease in difficult environments. These changes will improve efficiency, accuracy, and transparency across different industries, placing barcode technology as the foundation of automation.

FAQS (Frequently Asked Questions):

What do barcodes do?

Barcodes store and encode information in a machine-readable format, helping with the identification, tracking, and management of products, assets, and documents.- What industries use barcode systems?

Business sectors that incorporate barcode systems cover retail, healthcare, logistics, warehousing, manufacturing as well as food and beverage, and even government organizations. - What barcodes set off alarms?

Barcodes themselves do not set off alarms, but security tags with Electronic Article Surveillance (EAS) technology can trigger alarms if not deactivated at checkout. - Where are barcodes used?

Barcodes are used in retail stores, warehouses, hospitals, airports, postal services, libraries, and manufacturing plants. - Where were barcodes first used?

The first barcode was scanned in 1974 at a Marsh supermarket in Ohio, USA, on a pack of Wrigley’s chewing gum. - Are barcodes universal?

Some barcodes, like UPC (Universal Product Code) and EAN (European Article Number), are globally recognized, while others are region- or company-specific. - Are barcodes the same at different stores?

Retail barcodes (UPC/EAN) are the same for the same product in different stores, but some stores create unique barcodes for internal tracking and promotions. - Can barcodes have letters?

Yes, alphanumeric barcodes like Code 39 and Code 128 can contain both letters and numbers. - How do barcodes work?

Barcodes consist of black and white bars or squares that represent data. A scanner reads the pattern by detecting light reflection, converts it into an electrical signal, and decodes it into useful information. - Which barcodes are for which country?

EAN-13 barcode prefixes indicate the registered country of the manufacturer, for example:

00–13: USA & Canada

40–44: Germany

45–49: Japan

50: UK

89: India

690–695: China - Why are barcodes on stamps?

Barcodes on stamps help with mail tracking, fraud prevention, and sorting automation in postal services. - Will barcodes set off alarms?

Barcodes alone do not trigger alarms, but security tags with embedded EAS systems can if they are not deactivated properly.

Comment

0Comments

No comments yet.