AI-based visual inspection in the electronics manufacturing industry provides an advanced method for ensuring the quality and integrity of components. These systems utilize advanced algorithms and machine learning techniques to analyze images of electronic components, such as Printed Circuit Boards (PCBs), with high speed and accuracy.

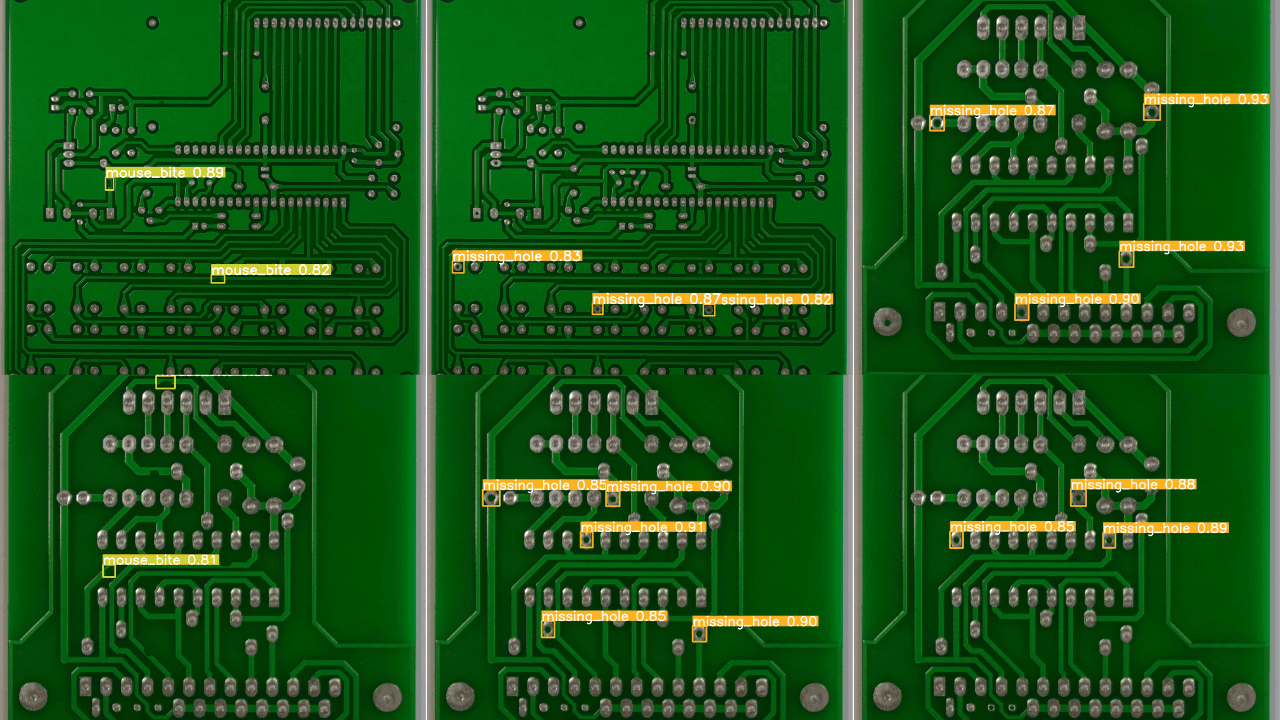

Defects in electronics boards may compromise the physical integrity of the board and are not always visible to the naked eye. Shorts and unintended electrical connections pose significant hazards as they can render a board defective or cause complete failure. The xis.ai visual inspection system excels in highlighting “open circuits,” which are breaks in the electrical continuity essential for device operation. Trained to detect a variety of defects, including such as spurious copper, minute nicks or breakages on the edges of the board, the system provides clear and accurate identification.

The integration of artificial intelligence in visual inspection not only enhances defect detection but also streamlines the production process. The data collected by the xis.ai visual inspection system offers valuable insights into the production process, facilitating continuous improvement and optimization. With each analysis, the AI system learns, enhancing its accuracy and efficiency, thereby establishing a robust production environment that consistently maintains efficiency and actively works to reduce errors.