In the manufacturing sector, the paramount objective is to attain Zero-Defect Packaging. The integration of Deep Learning with AI and computer vision stands out as a pivotal factor in achieving this goal. Beyond ensuring a faultless approach, the technological fusion enhances system efficiency, cuts production costs, and guarantees consumers top-quality products. This approach aligns with the industry’s commitment to precision and quality, recognizing packaging’s dual role in offering crucial user information and serving as a marketing tool.

Understanding AI-Powered Defect Identification:

AI-based visual quality inspection systems have become the backbone of real time packaging defect detection. These systems employ advanced algorithms to inspect images or videos of packaging, detecting defects such as mislabeling, packaging errors, and printing irregularities. Additionally, when coupled with optical character recognition and augmented reality, computer vision even extends its capabilities to scanning labels on packages in motion .

This comprehensive approach ensures that every aspect of packaging meets the stringent quality standards set by manufacturers. What makes these systems truly exceptional is their ability to identify anomalies that may escape the human eye, ensuring a meticulous inspection process

xis.ai — Pioneering Real-Time Product Defect Detection:

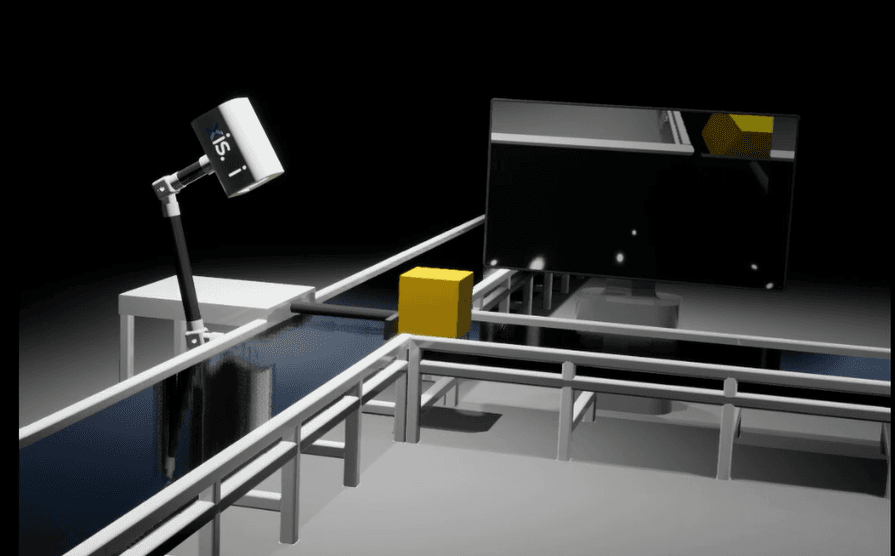

xis.ai introduced an Advanced AI-driven Visual Inspection System, meticulously designed to elevate the standards of real-time product defect detection in professional manufacturing environments.

The model can be configured or fine-tuned to accommodate various shapes, sizes, and materials in the manufacturing industry. Comprising cutting-edge components, the system seamlessly integrates a high-resolution camera for image capture and sophisticated software for analysis .Products briefly enter the camera’s field of view, illuminated by a strobe light if needed, capturing images at 60 frames per second for processing by the software.

The integration of the detection system with robotic arms involves a coordinated process to efficiently identify and handle defective packages. Here’s an elaboration on how this integration works:

1. Real-Time Video Receiving:

Cameras on the conveyor belts capture data and transmit frames in real-time to the server, ensuring a constant flow of information for analysis.

2. Optimization Techniques:

To tackle challenges in real-time inference, optimizing techniques like Quantization, Pruning, and Hardware Acceleration are employed for achieving low latency and maintaining high accuracy.

3. Packaging Defect Detection:

The detection system, equipped with AI-powered visual inspection, processes frames in real-time to identify defects in packaging boxes on the conveyor belt.

4. Automatic Classifier:

Upon detecting a defective package, the detection system communicates relevant information, such as the nature of the defect and the location on the conveyor belt, to the Automatic Classifier. The Automatic Classifier, using probability values generated during the defect detection phase, processes the classification of the packages and determines whether a package is defective.

5. Command to Robotic Arm:

Upon detecting and categorizing a faulty package, the Automatic Classifier promptly dispatches precise removal instructions to the robotic arm, outlining the grasp style, pickup location, and destination. The robotic arm swiftly carries out the removal, guaranteeing both efficiency and security in the process.

In this technological journey, xis.ai visual inspection system ensures manufacturing without defects, improves system efficiency, optimizes production costs, and assures that products delivered to consumers meet the highest quality standards.