Real-Time Confectionery Defect Detection With AI-Powered Computer Vision

Recent Post:

The art of baking cookies and other confections has delighted generations, but achieving consistent quality on a large scale takes work. The global cookie market continues to grow, reaching $30.6 billion in 2020 and is projected to hit $44 billion by 2026. In reaction to increasing consumer expectations but the demand for productivity and cost elements, manufacturers derive new technologies.

AI-based computer vision technology is transforming the food industry by allowing defects to be identified in real-time, optimizing quality control processes, and ensuring that treats meet standards. Meanwhile, automated inspections help manufacturers upgrade product quality, minimize wastage, avoid food recalls, enhance customer satisfaction, and endear brand trust and loyalty. They are lending an Optimal System and a New Benchmark for the Food Manufacturing Industry. Computer Vision Systems can align production lines to maintain safety and optimize with the help of computer vision systems in production lines using AI from collected data.

The Importance of Quality in Confectionery Manufacturing

Baked goods and non-baked goods are beloved treats, and consumers demand high appearance, texture, and taste standards.

Defects can tarnish a brand’s reputation and erode customer trust. These common defects are:

1. Appearance Defects:

- For Color Deviation:

1. AI systems differentiate mismatched or uneven colours caused by improper mixing or heating.

- Surface Imperfections:

1. Cracks or fractures on chocolate, candies, or coatings.

2. Porous or Non-Porous Finishes Like Bubbles Or Grains

- Blooming:

1. Chocolate Bloom: Actual visible white or greyish coating and rough, powdery texture from moisture.

2. Air bubbles: These appear in chocolates or hard candies as clear pockets.

3. Deformation or dimensions discrepancies: Irregular shape or non-uniform size in moulded or extruded goods.

2. Texture-Related Visual Defects

- Deformation: Warped or collapsed products due to handling or cooling issues.

- Uneven Coating: AI can identify irregular chocolate or icing layers.

3. Packaging Defects

- Seal Integrity Issues: AI-powered vision systems can detect improper sealing or misaligned labels.

- Foreign Materials: Identifying unwanted particles or contaminants in transparent packaging.

- Damaged Packaging: Torn, punctured, or dented wrappers and containers.

4. Contamination and Hygiene Defects

- Foreign Particles: Detecting visible contaminants like hair, plastic, or metal.

- Mould or Fungal Growth: Early-stage mould visible on products.

5. Structural Defects

- Ingredient Separation: Layer separation in products like nougat or layered candies.

- Breakage: AI can identify broken pieces during production or packaging.

6. Consistency and Quantity Defects

- Underfilled or Overfilled Products: AI can measure weights and shapes to ensure accurate filling.

- Inconsistent Product Count: Detecting missing items in packaging.

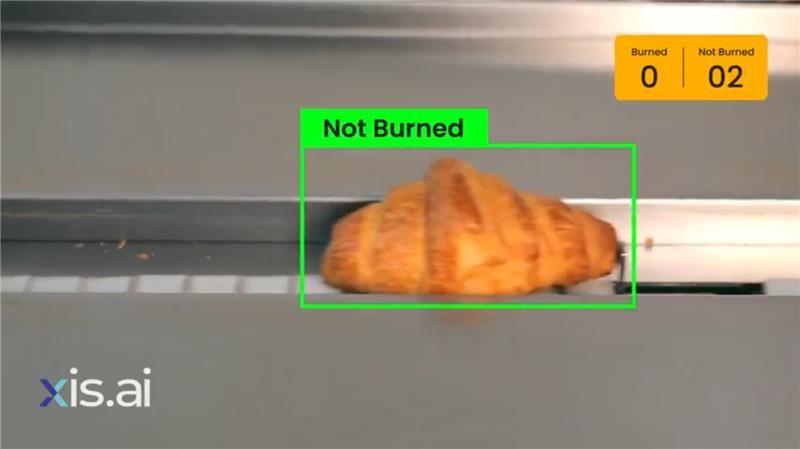

To keep this bake ideal, part of the challenge is to have the oven running all day and night to prevent an over-fluctuation in temperature when batch baking these confectionaries. Manual inspection methods find it difficult to identify these defects, particularly at large scale. To meet rising demands, the xis.ai Visual Inspection System powered by AI plays a significant part. AI systems consistently evaluate all the baked and unbaked treats and automatically adjust oven temp.

How Computer Vision Enhances Quality Control in Confectionery Manufacturing

Computer vision utilises artificial intelligence (AI) and machine learning (ML) to automate real-time defect detection, transforming quality control in production by specific methods.

1. Image Acquisition:

High-speed industrial cameras capture high-resolution images or videos. These cameras pair designed lighting to capture cookies moving along the production line. These cameras can see all angles and features of the baked and unbaked treats.

2. Preprocessing:

The images captured undergo preprocessing, enhancing contrast, normalising lighting, and removing noise, ensuring optimal visualization of confectionery features. Additional steps like filtering, resizing, and contrast normalisation prepare the images for accurate defect identification.

3. Feature Extraction:

The defect detection process refines by extracting' texture, shape, and colour. These features help identify irregularities and compare confectionery goods against predefined standards.

4. Defect Detection and Classification:

AI models, trained on extensive datasets of images, analyse features to detect and classify defects.

Techniques include:

- Object Detection: Identifying the presence, size, and alignment.

- Colour Analysis: Detecting discolouration or burnt areas.

- Edge Detection: Recognizing cracks, chips, or shape irregularities.

- Feature Matching: Ensuring toppings like chocolate chips, caramels, fudges, sugar granules, or decorations are present.

The AI algorithms compare treat attributes with normal and defective samples, classifying cookies into "good" or "defective" categories. They also identify the type and extent of defects.

5. Real-Time Decision Making:

When the defect is detected, the AI system notices the rejection sorting. Real-time processing ensures sure smooth operation of the production line.

Cookies on an automatic conveyor belt or line, baking in a confectionery factory.

Key Benefits of Real-Time Cookie & Confectionery Defect Detection

AI systems can detect subtle defects invisible to manual inspection, maintaining reliable, high-quality products.

- Automated detection speeds up production, reducing labour costs.

- Manufacturers identify Defects earlier, which can minimise waste and allow for the repurposing of off-spec baked goods into other products, such as crumbs or dough.

Conclusion:

Computer vision-based real-time cookie and confectionery defect detection disrupts the entire food manufacturing industry by utilising artificial intelligence and automation to deliver standardised quality, improved operational efficiency, and reduced wastage. On integration into the baked and unbaked goods production lines, these solutions allow accurate and efficient quality control by automating defect detection and providing manufacturers with AI-powered insights. This technology will continue to develop and become part of standard food production, enabling manufacturers to boost productivity, cut down on waste, and produce high-quality confectionery items that consumers enjoy time after time.

Comment

0Comments

No comments yet.