The Ins and Outs of AI-Based Visual Inspection: Principles and Practical Uses

Recent Post:

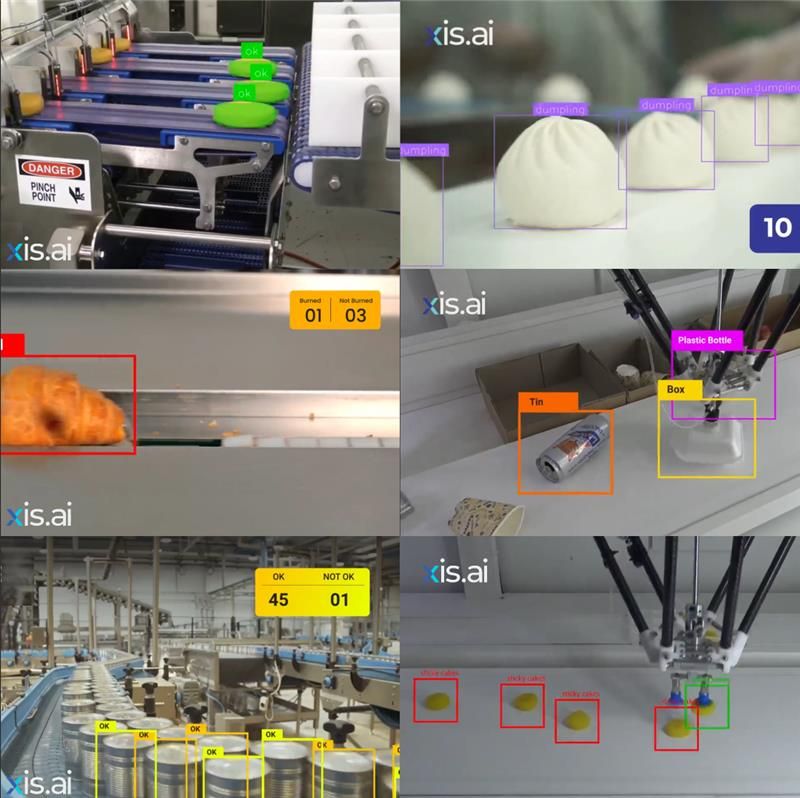

In various industries and production lines, people usually check products by looking at them, which takes time and can lead to mistakes. But now, with new technology like AI-based visual inspection, things are improving and quality control consistency is guaranteed. AI visual inspection helps make sure products are checked quickly and accurately. It is mainly useful for grading, sorting, and processing materials. These automatic systems used to have limits, but now, with better machine learning and artificial intelligence, they work much better. This new tech is changing how we can do inspection quality control, making it more accurate and faster across many industries.

What is Visual Inspection?

Visual inspection is a method used in manufacturing to assess products, components, or materials for defects and ensure they meet established standards. People or automated systems can perform this process, looking for problems like flaws or inconsistencies.

During the manufacturing processes checking things carefully early helps make products better, saves materials, and makes sure they follow all the rules.

In earlier times, inspection people had to do everything by eye. And their speed was not very quick at all, the current conditions lost their real objective. The manufacturer can depend on smooth checks for faster and higher quality products with these intelligent machines.

Automated Visual Inspection System

What Is AI-Based Visual Inspection?

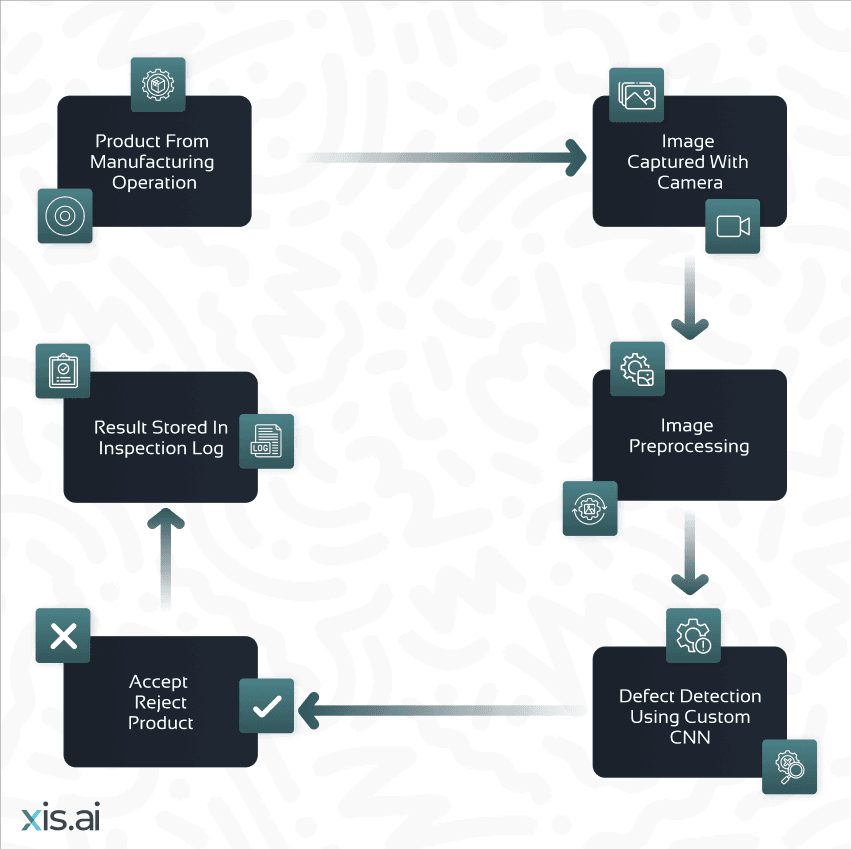

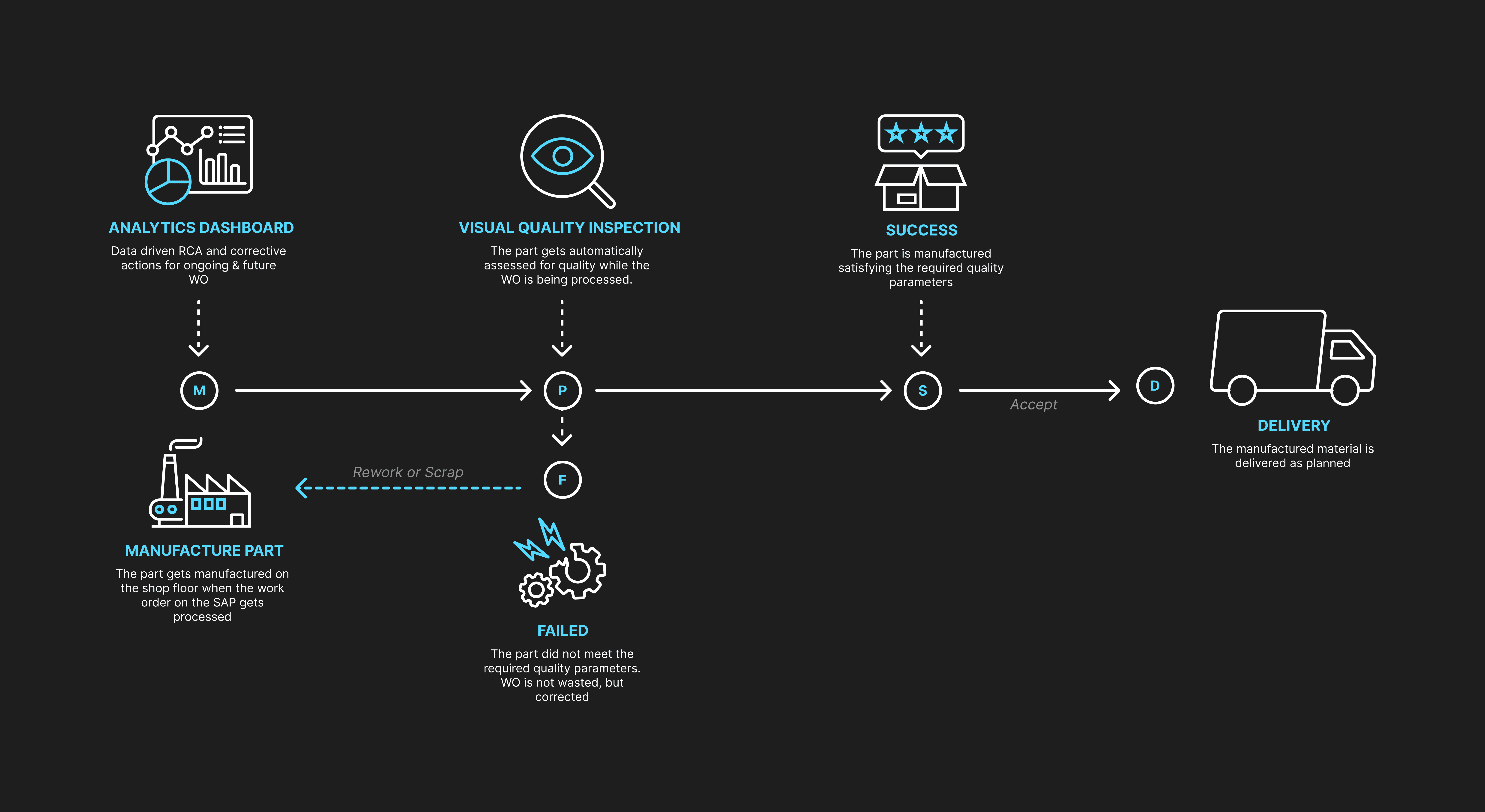

AI-based visual inspection utilizes Artificial Intelligence (AI) and computer vision to automatically inspect and evaluate products or parts, improving quality inspection services. Dissimilar to traditional methods, it uses advanced algorithms, as well as machine learning and deep learning techniques, to thoroughly analyze images or videos for any defects, inconsistencies, or distinctive features.

Artificial Intelligence-based Smart Quality Inspection Methodology.

Key Benefits AI-Based Visual Inspection

Increased Accuracy: AI systems capture nuances likely to be overlooked by human inspectors improving the quality management process.

Fast Inspection: AI improves the quality inspection process by performing tasks that would take hours to be inspected by humans in a few minutes, thus reducing the production cycle duration.

Consistency: There are no distractions from fatigue or mistakes of any kind that compromise the reliability of AI system quality checks over time.

Cost Reduction: In visual inspection, AI helps to cut production costs by reducing labor costs, rework costs, and costs of defects when they occur.

Scalability: Management technologies can scale up easily with increased production outputs and visual quality inspection can still be maintained, this can not be the same for manual inspection.

Flexibility: New and surprising faults can be located by the AI system which makes it more adaptable to other inspection specifications.

Data-Driven Insights: The analysis incorporates specific examples such as insights from AI visual inspection systems, which can be used to plan and maintain products, processes, and equipment.

Streamlined Production: Using these methods to carry out visual inspections reduces the workload on production lines and greatly enhances productivity in the related fields.

Use Cases of AI-Based Visual Inspection:

Automotive Sector: In the automotive sector it recognizes shortfalls which include scratches, dents, missing parts, and defective parts. It also assesses the paint, and parts assembly, and conducts weld quality visual inspection including checking for weld seams.

Semiconductor sector: AI detects wafer-level flaws such as scratches or bubbles during the wafer stage.

Food and Beverage Industry: Checks for contaminants in food products, foreign bodies, leakage in the packaging, or quality control of food products.

Pharmaceutical Industry: The flaws are identified with a visual inspection of medicine packaging and carry out quality checks by looking for air bubbles, dirt, or skin labels.

Medical devices: AI systems guarantee the accuracy, sterility, and safety of medical devices.

Electronics Manufacturing: In electronic manufacturing, AI-based visual inspection systems are used to check defects in small parts like chips, circuit boards, and solder joints.

Agronomic activities: It is easier to sort and classification of fruits, vegetables, and nuts of the different types including unearthing the crop production levels through imaging of the fields’ images.

Security Personnel and System: Improves security as it can recognize unauthorized individuals & as well raise an alarm when abnormal activities are detected in a specified time frame.

Industrialization: AI systems continue to seek and identify superficial imperfections and misalignments as well as aesthetics on various artifacts.

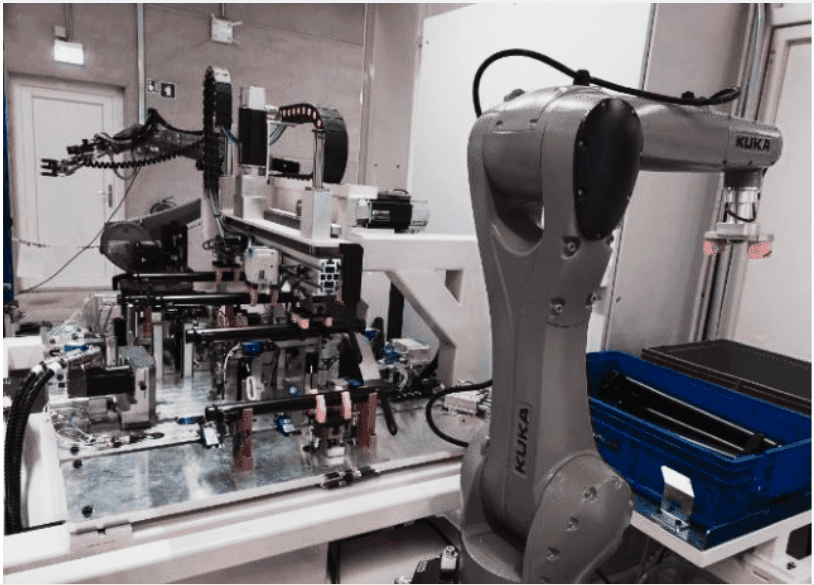

AI Technology smart factory

Advantages of AI-based Visual Inspection Systems:

Enhanced Accuracy: AI systems have demonstrated the ability to identify the tiniest of defects as compared to normal human inspectors hence enhancing the quality of control.

Increased Efficiency: With the AI-based systems there is no exhaustion this helps alleviate the inspection process and ease the bottlenecks.

Consistency: It presents consistent and dependable outcomes and manages inconsistency in human performance due to fatigue.

Cost Reduction: It lessens the cost of labor and the error ratio which in effect reduces the amount spent on product recalls, repairs or wastage of products.

Automation: It helps to decrease the level of manual inspection with the possibility of companies mechanizing repetitive processes and allocating employees to more productive zones.

Real-time Monitoring: It eliminates the delay of sending the information to supervisors as soon as the defect or anomaly is detected so that rectification can be executed very fast.

Continuous Improvement: AI technologies over time improve in handling the data which may lead to a turnaround in analysis by identifying new, or shifting defaults explaining underlying causes of change efficiency and precision enhancement.

Versatility: AI can be deployed in numerous work premises such as the automotive, pharmaceutical, and electronic sectors among many others without limitation and thus suitable for many inspection works.

Scalability: It is simple to scale an application to any production level due to its flexible implementation depending on the company size and inspection requirements.

Safety: There is no onsite human risk as AI-based visual inspection systems can be used in high-risk situations.

Predictive Maintenance: Using AI technology, an employer can always monitor an equipment’s status, hence taking precautionary measures even before an equipment failure occurs, helping reduce downtimes.

Data-Driven Insights: gladly, every such report can provide insights and analytics that will allow companies to improve their business processes, decrease imperfections, and raise the level of the product.

The Importance of Data Annotation in Visual Inspection

Data annotation is an essential process in computer vision for visual inspection tasks. It involves labeling images or videos with specific attributes like object boundaries, classifications, or semantic features. The following techniques are helpful for visual inspection:

Training AI Models: Annotated data improves how the computer vision models interpret and reach decisions, hence leading to a better inspection process.

Quality Control and Finding Defects: During the production process liability, defects enhance the ability of the models to recognize and classify defects in the respective products accurately.

Understanding What’s in Images: The provision of data annotation enables the ability of the models to identify and locate different objects and even comprehend their relationships in an image.

Handling Complex Tasks: Certain visual inspection operations are perplexing and need an individual’s thinking. Skilled data laborers can address those challenging pieces of information thereafter enhancing the performance of the model.

Adapting to Different Industries: There are several areas that zoom inspection such as the medical, automobile, and other applications. The structure of a model is designed to meet the demands of a particular industry through data annotation.

Checking Model Performance: Labeled data is utilized in assessing the performance of a model. It is done by evaluating the prediction of the model towards the prediction in question thus helping improve the algorithm.

Working Together with AI: Data annotation allows room for a collaborative approach where humans and AI work together. While AI is good at many processes, some scenarios require human genius which makes the whole exercise more accurate.

Conclusion:

AI-based visual inspection represents a significant advancement in quality assurance and manufacturing processes. The use of AI in visual inspections takes quality assessment to a whole new level due to its precision, uniformity, and efficiency which have never been experienced before. Its impact on control of quality, efficiency, and accuracy is disruptive at the very core of industries. There are hardly any steps that remain to be performed with the assistance of human beings if most of the quality assessment processes have been delegated to the boards with less and less use of common human power in extreme cases for the intelligent machines with smart learning capabilities process the visual information at a gigantic extent and a very high speed. As industries continue to adopt this technology, the reliance on human oversight diminishes, enabling faster processing and reducing operational costs. AI-based visual inspection increases production capacity and helps businesses deliver high-quality, reliable products.

About xis.ai :

xis.ai automates visual quality inspection with AI and robotics. With a camera and no code computer vision platform that enables non-technical industrial users to develop, deploy, and use Automated Visual Inspection (AVI) in any industry in minutes.

xis.ai automates visual quality inspection with AI and robotics. With a camera and no code computer vision platform that enables non-technical industrial users to develop, deploy, and use Automated Visual Inspection (AVI) in any industry in minutes.

Comment

0Comments

No comments yet.